The Cybertruck hasn’t even hit the market yet, and Elon Musk already is lamenting that Tesla has dug its own grave.

Its stainless steel body may be able to withstand bullets and arrows, but it’s going to be a bear putting the panels together. It will be Tesla’s first high-voltage vehicle, offering the benefit of faster charging, but also potential pitfalls. And it will be Tesla’s only product dependent on in-house battery cells that are years behind schedule.

In these respects and others, the Cybertruck will be a big step backward from how Tesla has progressed in its approach to car-making. The last vehicle Musk spoke about the way he’s described the Cybertruck was the Model X, the sport utility vehicle that’s never reached high volumes because of what its CEO described on several occasions as hubris.

“Model X became kind of like a technology bandwagon of every cool thing we could imagine all at once,” Musk said of the SUV in May 2017. “That is a terrible strategy. You really want to start off simple and add things over time.”

Emphasis on simplicity and designing for ease of manufacturing served Tesla well with its next product, the Model 3 sedan, and the smash-hit Model Y SUV that followed. The two were the first electric vehicles to break into the mainstream, making Tesla far and away the most valuable automaker and its CEO the world’s wealthiest man.

Musk remarked when the Model 3 was starting production in 2017 that it wouldn’t have “all sorts of bells and whistles” like the Model X, which featured double-hinged doors and floating second-row seats.

Last month, on the same earnings call where Musk referred to Tesla digging its own grave, he warned that the Cybertruck “has a lot of bells and whistles”.

‘Blood, sweat and tears’

Tesla may eventually overcome what its CEO has described as enormous challenges making the Cybertruck in high volumes, and without burning through cash. But Musk himself has estimated this will take 12-18 months of “blood, sweat and tears”. He’s also said Tesla is unlikely to reach an annualised production rate of 250 000 Cybertrucks until sometime in 2025.

Ahead of the company starting Cybertruck deliveries on 30 November, one analyst has gone so far as to suggest the company should cancel the vehicle, saying it probably would be positive for Tesla’s shares.

“When Elon Musk says it’s going to be hard, listen,” said Stephanie Brinley, an associate director at S&P Global Mobility.

Read: Tesla gearing up to build sub-R500 000 electric car

Musk has called Model X “the Fabergé egg of cars”, referring to the rare symbols of opulence crafted using precious metals and gemstones. “Probably nothing like it will ever be made again, and maybe it shouldn’t,” he said in January 2019.

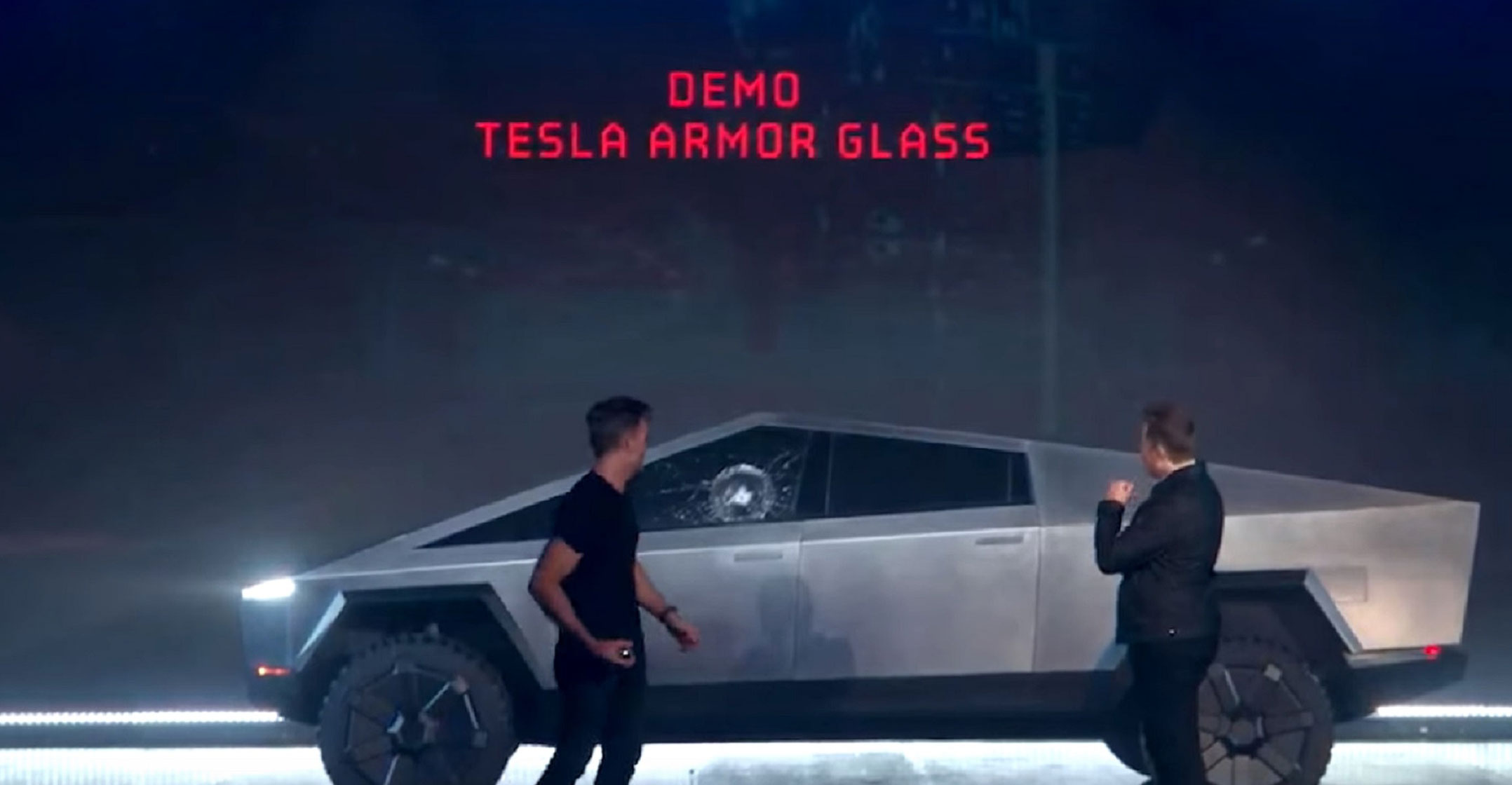

Ten months later, Musk strode onto a stage at Tesla’s design centre just outside Los Angeles and told a crowd of fans that bakkies had all looked more or less the same over the last century. The company wanted to try something different, he said.

Minutes later, the vehicle that rolled onto the stage through smoke, strobe lights and balls of fire lived up to the CEO’s billing as something out of the sci-fi film Blade Runner. The Cybertruck’s triangular roof, angular exterior and transparent-metal glass that shattered in a botched demo instantly became the stuff of memes.

Tesla started taking deposits for the vehicle, marketing starting prices ranging from US$39 900 to $69 900. The company initially said deliveries would begin no sooner than late 2021. Around the time it was supposed to start handing over the vehicle to customers, Tesla removed Cybertruck pricing and specifications from its website and hasn’t restored them since.

A key reason it’s taken the company two more years than expected to start deliveries was the decision to clad the vehicle with an ultrahard stainless-steel alloy, which Musk said his rocket company SpaceX also would use for Starship, its launch vehicle designed to someday reach Mars.

While stainless steel resists corrosion and doesn’t need to be painted, it can be costly and difficult to shape and weld together. It also tends to be heavier than steel commonly used for most car and truck bodies.

In late August — three months before Tesla’s scheduled start of deliveries — Musk wrote an e-mail to Tesla employees that leaked to an online forum. “Due to the nature of Cybertruck, which is made of bright metal with mostly straight edges, any dimensional variation shows up like a sore thumb,” the CEO noted. He ordered all parts for the vehicle to be designed and built to sub-10-micron accuracy, or 10 millionths of a metre.

When Franz von Holzhausen, Tesla’s chief designer, showed up to a car enthusiasts’ event in southern California early this month with a Cybertruck prototype, photos quickly surfaced showing misaligned fender flares and panel gaps wide enough to stick a finger through.

‘Wacky’ Cybertruck

“The problems that are very evident with the Cybertruck are problems with the concept itself,” said Eric Noble, president of The CarLab, an automotive product and design consulting firm. “The market wasn’t asking for a stainless-steel finish, wacky bed configuration, wacky roof line or wacky side visibility. Those are all answers to a question that the pickup truck market wasn’t asking.”

Tesla announced last month that it would adopt an 800V architecture for the Cybertruck, citing the cost savings this brings to heavy vehicles.

Read: Tesla aims to make 200 000 Cybertrucks a year

This will be a first for the company’s consumer vehicles, though it isn’t uncharted territory. Porsche brought an 800V system to market with the Taycan electric sports car in 2019. Hyundai also has offered one on the Ioniq 5, enabling the SUV to more quickly take in electricity.

While other manufacturers have pulled it off, the switch will involve some risk and expense.

“You’re changing many things — the charging infrastructure, all the way through the entire vehicle system,” Drew Baglino, Tesla’s senior vice president of powertrain and energy, said in April 2022.

“The advantages are small and the cost is high,” Musk added on the same earnings call. “Years from now, will it make sense to move to an 800V architecture? Probably. But it really needs a very big vehicle volume to pay for the cost of changing from 400V to 800V.”

Another risk factor for the Cybertruck has to do with batteries. In September 2020, Musk staged an event to tout several innovations Tesla was working on, including thicker, more voluminous cells. Baglino said at the time the company would get a 16% range boost from the new form factor alone (its 4680 batteries are 46mm in diameter and 80mm tall.)

Tesla has struggled to scale up 4680 battery production, which has in turn held up products including the Cybertruck and Semi. Almost a full year after hosting a delivery event related to the Semi a year ago, the company is still making the vehicle in low volumes, and only for PepsiCo, its initial customer, Deutsche Bank analysts wrote in a 14 November report, citing meetings with Tesla’s head of investor relations.

Read: Tesla’s new AI supercomputer changes the game: Morgan Stanley

When asked during an earnings call last month how many Cybertruck deliveries he expected in 2024, Musk demurred.

“If you want to do something radical and innovative, and something really special like the Cybertruck, it is extremely difficult, because there’s nothing to copy,” he said. “You have to invent not just the car, but the way to make the car. So, the more uncharted the territory, the less predictable the outcome.” — Reporting with assistance from Sophie Caronello, (c) 2023 Bloomberg LP