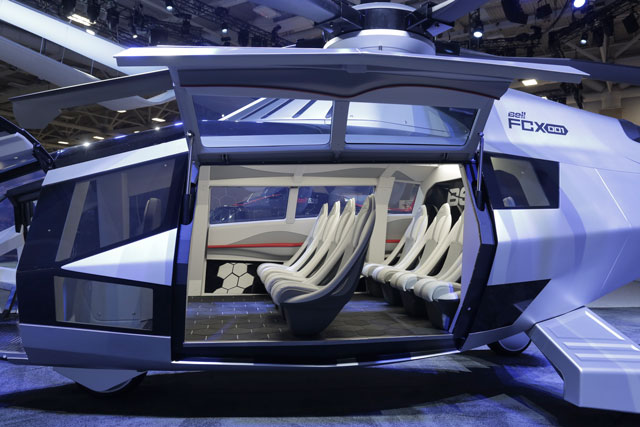

At the helicopter industry’s largest trade show last week, dozens of aircraft were parked over seven acres of Dallas, Texas convention centre space. Yet only one generated a constant crowd as more than a thousand people gathered around Bell’s FCX-001 chopper.

Just as car makers roll out concept vehicles at auto shows, Bell Helicopter Textron decided last year to build a helicopter to display its most cutting-edge technologies, said Scott Drennan, director of innovation at Fort Worth, Texas-based Bell. Widely known for the UH-1 “Huey” helicopters flown by the military in Vietnam, Bell’s research today is likely to appear in choppers many years from now.

The FCX-001, which made its public debut at the three-day Heli Expo 2017, is more of a statement than a prototype for an industry that’s weathered deep retrenchments in the oil and gas fields. The FCX concept carries 8-12 passengers but isn’t meant to fly. Instead, it features several chunks of tech that will likely migrate into production models in coming years, Drennan said.

“The goal was to let the creative team pull us closer to our physics and engineering boundaries or to turn our point of view such that the perspective was really different,” he said. “Then the engineers would pull those creative types closer to the engineering and physics boundaries.”

Single rotor

Traditional helicopters feature two rotors, one on the roof and one at the tail. In the future, Bell predicts that only one will be used, due to “anti-torque” technology in the boom that will make the smaller aft blades obsolete. This technique is also expected to lower the helicopter’s overall noise level — a critical consideration for buyers and regulators, Drennan said. Bell engineers see promise in the concept and plan to begin testing the approach “in earnest” this summer, he said.

Morphing blades

The ability to alter the rotor blades during forward flight offers two big advantages — fuel efficiency and an overall lower noise profile. But there’s one enormous hurdle: the engineering challenges that arise from changing the blade shape in flight. This technique may not find its way into production for many years.

Hybrid engine

The FCX is based on the idea of mixing a conventional turboshaft for the main rotor with an electrical motor to power the anti-torque tail system. The two would be decoupled, allowing for the rear system to be shut off as needed.

Energy-harvesting fuselage

Bell is exploring advanced carbon fibres and other materials that could help to harvest vibrational energy and convert that to electricity for the motor.

Virtual flight deck

The twin-engine FCX has a single pilot seat but no instruments. Flight controls would be governed by an augmented reality helmet, akin to some of the technology deployed in advanced fighter jets. Flight computers would handle some of the routine and more perilous manoeuvres involved in safe flight, Drennan said. Passengers also would wear a similar helmet for communications and entertainment. At some point, a helicopter like the FCX would fly autonomously. — (c) 2017 Bloomberg LP