Additive manufacturing — or 3D printing — is 30 years old this year. Today, it’s found not just in industry but in households, as the price of 3D printers has fallen below US$1 000. Knowing you can print almost anything, not just marks on paper, opens up unlimited opportunities for us to manufacture toys, household appliances and tools in our living rooms.

But there’s more that can be done with 3D printed materials to make them more flexible and more useful: structures that can transform in a pre-programmed way in response to a stimulus. Recently given the popular science name of “4D printing”, perhaps a better way to think about it is that the object transforms over time.

These sorts of structural deformations are not new — researchers have already demonstrated “memory” and “smart material” properties. One of the most popular technologies is known as shape memory alloy, where a change of temperature triggers a shape change. Other successful approaches use electroactive polymers, pressurised fluids or gases, chemical stimulus and even in response to light.

In a paper published in Nature Scientific Reports, we looked at the design of complex self-deformations in objects that have been printed from multiple materials as a means to customise the object into specific forms.

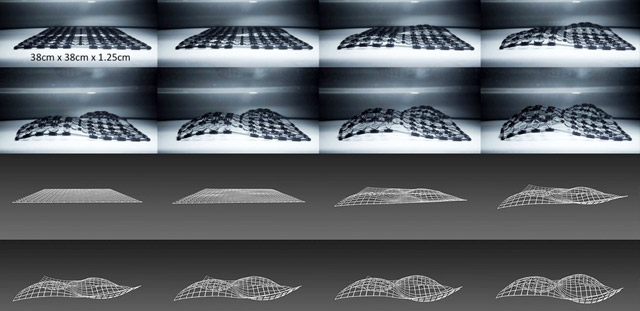

Unlike many others who have demonstrated how to bend simple paper-like shapes, we constructed a two-dimensional grid structure that deforms itself by stretching or shrinking across a complex three-dimensional surface.

Imagine dropping a flat stretchable cloth onto a randomly shaped object, where the cloth moulds over the shape beneath it. In geometrical terms, as the curvature of the cloth changes to fit the object, the distances and areas alter. We took this into account by providing a solution that copes with bending and also expansion in size, and came up with several designs that demonstrated that this is possible.

Head of the MIT’s Self-Assembly Laboratory, Skylar Tibbits, started this line of research a few years ago with expanding materials and simple deformations. The collaboration of researchers from MIT’s Camera Culture group and Self-Assembly Laboratory and the companies Stratasys and Autodesk Inc took this further.

Our approach was to print 3D structures using materials with different properties: one that remained rigid and another that expanded up to 200% of its original volume. The expanding materials were placed strategically on the main structure to produce joints that stretched and folded like a bendy straw when activated by water, forming a broad range of shapes. For example, a 3D-printed shape that resembled the initials “MIT” was shown to evolve into another formation that looks like the initials “SAL”.

What now?

We imagine there’s a wide range of applications such as home appliances and products that can adapt to heat or moisture to improve comfort or add functionality.

Childcare products that can react to humidity or temperature, for example, or clothes and footwear that optimise their form and function by reacting to changes in the environment.

There are also uses for pre-programmed self-deforming materials in healthcare — researchers are printing biocompatible components that can be implanted in the human body. There are many more uses these could be put to if they can be manufactured to change shape and function without external intervention from a surgeon. Individually designed cardiac tubes are one good example.

This was a proof of concept for self-transforming materials, with an easy production process and an available suite of tools to customise and analyse the process. But even so, this is just scratching the surface — in the future we aim to produce larger structures which can handle more complex transformations, as well as smaller, miniaturised models which can be used in the body. While we found the deformations could be applied and reversed repeatedly, the material degraded after a while, so we need to improve its long-term durability.

With 4D printing, there’s a lot to play with. Now that 3D printing has captured our imagination, just think what adding time to the equation could do.

Dan Raviv is postdoctoral fellow at the Massachusetts Institute of Technology

Dan Raviv is postdoctoral fellow at the Massachusetts Institute of Technology- This article was originally published on The Conversation