Intel plans to spend US$20-billion on a chip-making hub on the outskirts of Columbus, Ohio in the US, which the company expects to grow to be the world’s biggest silicon manufacturing site, according to a person familiar with its plans.

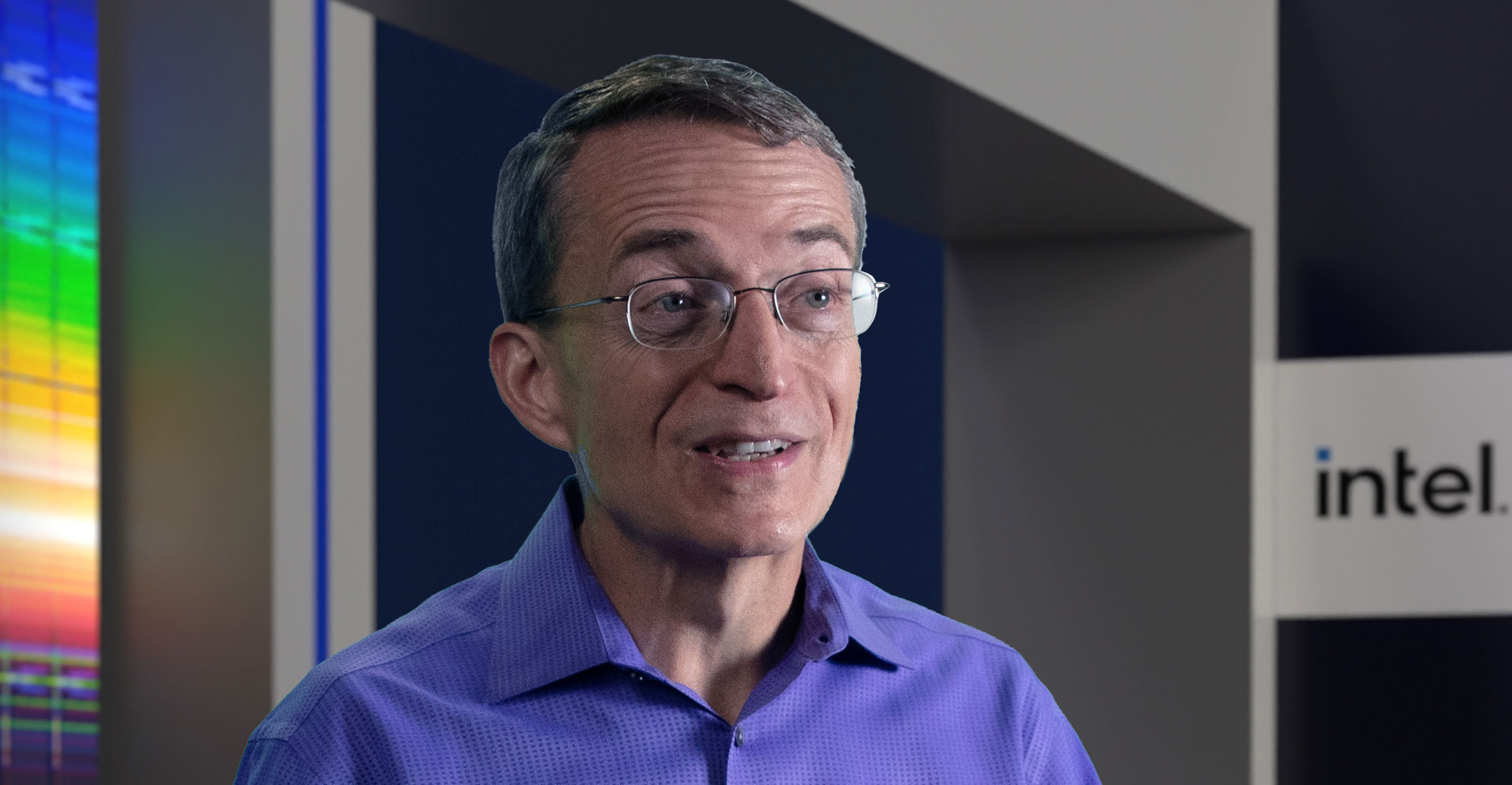

The chip maker will begin construction of two fabrication plants on a 1 000-acre site in New Albany, which it expects to be operational by 2025, said the person, asking not to be identified before a planned public announcement. Time magazine reported the plans earlier, citing an interview with CEO Pat Gelsinger.

He said the Santa Clara, California-based company will use the location as a hub to research, develop and manufacture its most advanced chips and will have the option to expand to 2 000 acres and up to eight fabs.

“We helped to establish the Silicon Valley,” Gelsinger told Time. “Now we’re going to do the Silicon Heartland.”

Intel’s leader has been vocal about the need to build more chip factories in the US and Europe, areas where manufacturing of the vital electronic components has declined precipitously. Gelsinger has argued that a rebalancing of production is needed to reverse its increasing concentration in East Asia. He has pointed to the pandemic-induced supply-chain crunch and increasing geopolitical tension between China and the US as evidence that Western governments need to find cash to persuade chip makers to relocate.

Adding Ohio to its list of locations, not traditionally an area associated with the technology industry, adds to the greater geographical diversity that Gelsinger has championed. Intel is also looking at sites in Germany, Italy and France for new factories, test and assembly plants, and research and design centres.

Taxpayer money

Putting some of Intel’s billions of dollars in capital expenditure to work in a new location for the company — it currently has plants in Oregon, Arizona and New Mexico — may help bolster Gelsinger’s appeal for taxpayer money. That in turn will help cushion some of the drag on profitability caused by his ambitious plans to restore Intel’s manufacturing prowess and muscle in on the business of outsourced chip-making, an area dominated by Taiwan’s TSMC and Samsung Electronics Co.

This year, Intel’s CEO has budgeted a record amount of spending on new factories and equipment. But, highlighting the massive and growing cost of state-of-the-art chip-making, TSMC and Samsung are planning to raise the stakes even higher.

TSMC has set aside more than $40-billion for capital expenditure this year. That compares to Intel’s plan to spend up to $28-billion. Samsung will likely announce its 2022 plans on 27 January in its earnings release. Analysts, on average, predict a company-wide budget of about $36-billion. — Ian King and Vlad Savov, (c) 2022 Bloomberg LP