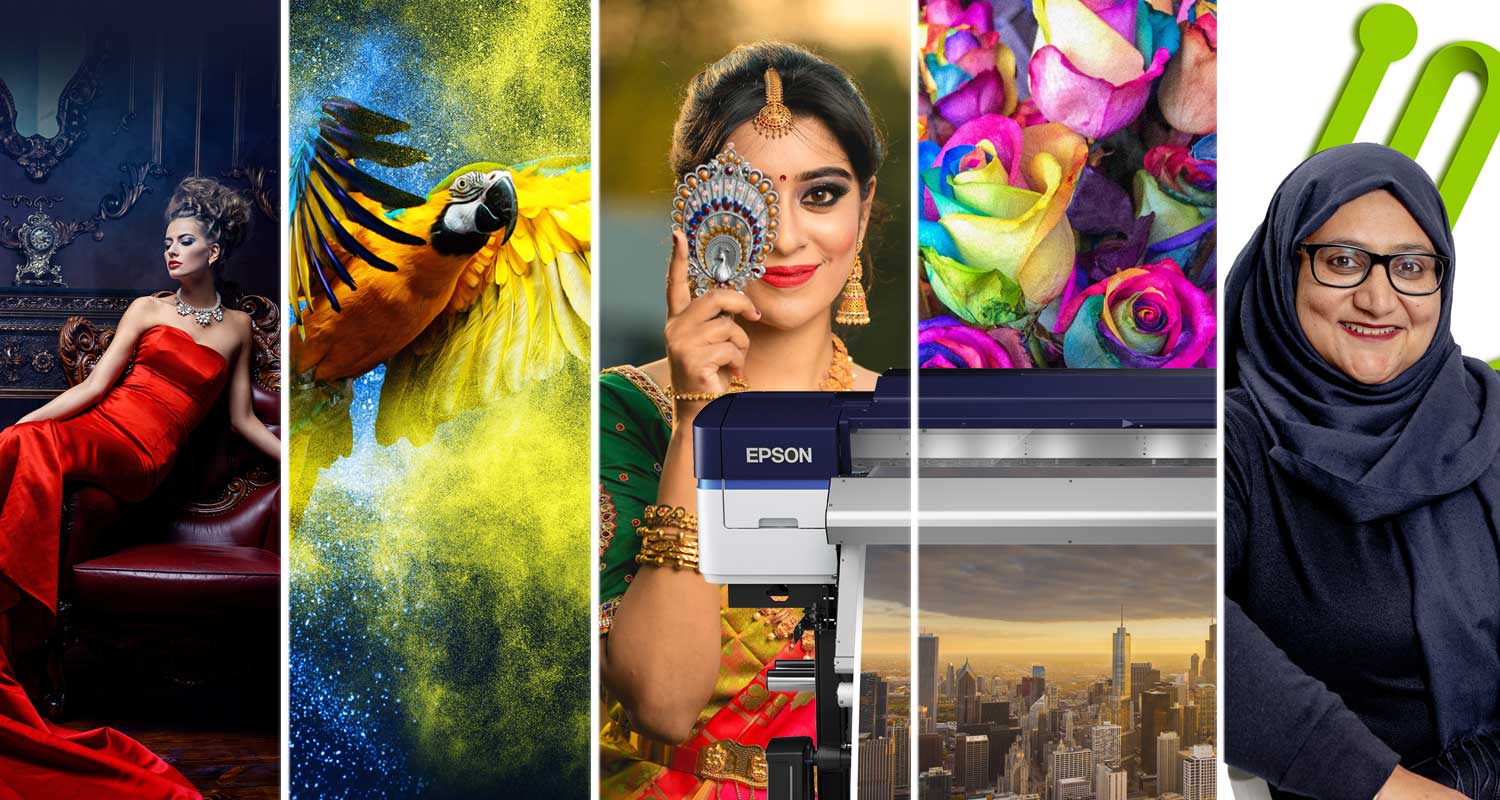

Large-format printing (LFP) is a specialist sector and faces its own unique challenges. Converting these into opportunities is the role of Kemtek’s business development manager, Aziza Mahomed.

Large-format printing (LFP) is a specialist sector and faces its own unique challenges. Converting these into opportunities is the role of Kemtek’s business development manager, Aziza Mahomed.

She shares her insights into how innovations from leading original equipment manufacturer Epson are transforming the economics of LFP converting – and providing outstanding customer outcomes.

Aziza highlights the three greatest challenges associated with large-format printing:

- Turnaround time (especially in the light of increasingly rigorous customer demands);

- Total cost of ownership (TCO) of LFP printing presses; and

- Meeting customer requirements in terms of colour register and compliance with non-negotiable branding parameters.

She said advances introduced by Epson are addressing each of these points head-on, and significantly lowering barriers to entry in the LFP space. Indeed, the needle has moved so far that the case for adding an in-house LFP capability is now much more compelling than it was even just a few years ago.

The changing face of LFP printing

The perception of high TCO has traditionally been a deterrent to converters looking to invest in an LFP press – however, this need not be the case. The reduction in TCO leads to much greater profit margins, even when allowing for some of the achieved cost savings to be passed on to customers.

A game-changer here has been the inclusion of cost calculators driven by built-in accounting software, which delivers very precise, real-time and actionable insights into yields and total print time. This allows for significant improvements in efficiency and leads directly to shorter pay-off times for technology investments.

Cost calculations can be customised to include details of factors such as associated labour costs and ink usage, with intuitive dashboard functionality able to highlight results against user-defined profiles.

Print on anything, anytime, anywhere…

Modern LFP printers also deliver expanded capabilities, which can unlock additional revenue-generating opportunities. These include the ability to print on a very wide range of media substrates, including those suitable for long-term outdoor display.

The introduction of Epson UV flatbed LFP printers (such as the Epson SureColor SC-V7000 in 2022) means that converters can meet the needs of more industries, thereby significantly expanding the potential customer base. Epson’s UV machines can print on virtually any substrate, and this development has eliminated the costly and time-consuming requirement to print onto vinyl, and only then stick the printed vinyl onto the final substrate.

Examples of the expanded capabilities of today’s LFP printers include truck bodies and other large vehicle wraps, in addition to glossy paper, vinyls, backlits and wallpapers. Multifunction machines can provide a precise match to customer requirements, whether for single-use or multipurpose printed media.

Advances in print quality mean that getting it right first time now happens every time, thereby eliminating the costs and wastage associated with repeated attempts at the same job. The resulting reductions in ink usage and substrate waste also contribute to more sustainable business models.

Brand integrity protection now standard

For many customers, their brand is their most valuable asset. This leads to them being fiercely – and understandably – protective of their brand equity, especially where this has been built up over time and at significant cost.

The value of brands and elements such as logos and colours means there is immense pressure on converters to reproduce these corporate identity elements with zero margin for error. Epson’s latest machines offer exceptional colour register – and, just as importantly – consistency, job after job. This is equally the case with consecutive jobs, or ad hoc print runs that may be weeks or even months apart.

Assisted by Kemtek and Epson, South African converters have been able to meet the exacting demands of some of the world’s most iconic brands and achieve deep, vibrant colours that keep visual communications on point and in the forefront of end users’ minds.

Try before you buy

Kemtek’s confidence in LFP printers manufactured by technology principal Epson allows converters to visit Kemtek’s City Deep Centre of Excellence to witness these versatile machines in action. Trust is earned, and in this case, it’s enhanced by allowing converters to have their own artwork printed on the Epson LFP presses so that they can see exactly the results they will be able to offer their customers.

This offer is now being rolled out to Kemtek’s regional branches across South Africa, as the LFP revolution gathers pace. Aziza said this was further evidence of the importance Kemtek places on relationships with its customers – in many cases, built up over years, if not decades. It is to these relationships that Kemtek attributes the company’s longevity – 2023 will see the “beyond technology” firm celebrate its 35th anniversary.

To connect with Kemtek and explore solutions that go beyond technology, visit kemtek.co.za or join the conversation on Facebook, LinkedIn and YouTube.

- Read more articles by Kemtek on TechCentral

- This promoted content was paid for by the party concerned