Four years ago, Anglo American couldn’t find any industry partners to support its idea of replacing open-pit mining’s monster diesel trucks with climate-friendly, green hydrogen-fuelled vehicles.

After investing as much as US$70-million (R1.1-billion) on its own to back the concept, the global miner revealed last week a new 220t vehicle capable of carrying about 290t of ore without producing global warming emissions in the process.

“It’s fair to say our desire to drive this was ahead of a lot of the industry’s ambitions,” Tony O’Neill, Anglo’s technical director said in an interview at Mogalakwena, the world’s biggest open-cast platinum mine, on Friday. “When it came down to timing we were pretty much alone.”

Anglo American, like rivals such as Glencore and Rio Tinto Group, are feeling pressure from investors who are concerned about global warming to cut carbon pollution. Replacing the mine haul trucks with hydrogen-fuelled ones would slash emissions at Anglo’s open-pit mines by 80%, a key step in reaching the company’s target of carbon neutrality by 2040.

Trucks make up “a big part” of the company’s greenhouse gas contributions, said Natascha Viljoen, CEO of Anglo American Platinum, the Anglo American subsidiary that operates Mogalakwena, in an interview.

Anglo’s prototype truck is part of the company’s NuGen programme, which also includes a solar-powered system for producing green hydrogen on mining sites. An electrolyser uses energy from the sun to split water and create hydrogen. Anglo enlisted the help of technology and hydrogen companies including Engie SA, First Mode Holdings, Ballard Power Systems and NPROXX.

‘Crystal clear’

Duncan Wanblad, Anglo American’s CEO, said the company considered synthetic fuels and biofuels before it became “crystal clear” that hydrogen was the solution. Anglo “built it from scratch”, he said about the programme in a speech at the mine, which is 290km north-east of Johannesburg.

There is still lots of work to be done to reduce the cost to convert existing diesel trucks to hydrogen. O’Neill said the company has spent tens of millions of dollars to launch its prototype. Regular diesel mine haul trucks are priced between $6-million and $7-million each. As the technology develops, economies of scale will kick in and costs will fall, he said.

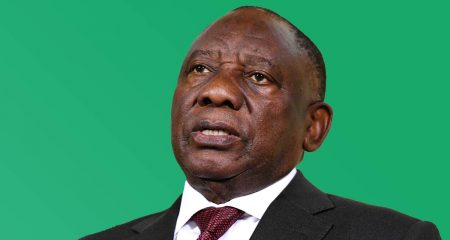

The prototype — a converted Komatsu 930E — is a blue and yellow behemoth that on Friday trundled up a mound of dirt and retrieved a full load of ore under the watchful eyes of executives, employees and President Cyril Ramaphosa.

It’s powered by a 1.2MW battery pack and eight 100kW hydrogen fuel cells.

The impact would be equivalent to taking half a million diesel cars off the road in terms of emissions reductions

The initial plan is to convert Mogalakwena’s 40 diesel-fuelled trucks to hydrogen by 2026. That will need 140MW of solar power and a massive expansion of the hydrogen conversion and storage facilities on site.

On cloudy days, the plan is to obtain power from wind and solar plants owned by the company in other parts of the country through the national grid to ensure that the operation of the trucks doesn’t contribute to global warming, said Carl van den Ordel, a mine engineer for Anglo at Mogalakwena.

By 2030, the company plans to convert its global fleet of 400 mine haul trucks — which operate across platinum, copper and iron ore operations — to hydrogen. The impact of that would be equivalent to taking half a million diesel cars off the road in terms of emissions reductions, the company said.

O’Neill said Anglo would like to sell the vehicles to its peers and believes the technology it has developed has other applications that could include use in trains and ships. O’Neill’s technical group is also looking at more efficient ways of extracting metals from ores and treating rocks with microwaves to ease the digging of tunnels. The latter is similar to the technology used by Elon Musk’s The Boring Company, he said. — (c) 2022 Bloomberg LP